Quality Control

Quality is Yulong’s non-negotiable article of faith. Recognising that the failure of one roller can destabilise entire systems, we enforce rigorous verification at every stage of the inspection process — there is no refuge for defects here.

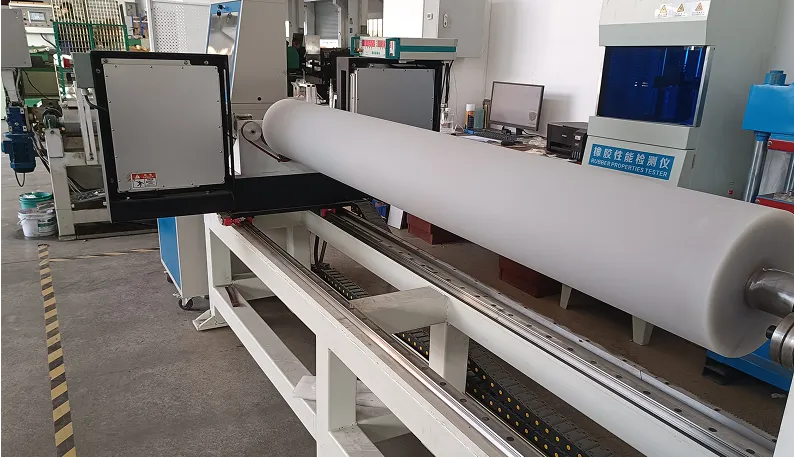

Machines Don’t Compromise

Production equipment is the cornerstone of quality control. Our manufacturing floor is equipped with precision-engineered machinery designed to eliminate variability. Our workshop is fitted with state-of-the-art production machinery, including a CNC lathe, an automatic welding robot and rubber wrapping equipment. Every tool undergoes predictive maintenance, and the combination of hardened steel infrastructure and adaptive technology makes defects architecturally impossible. Our equipment and personnel ensure that we uphold our zero-tolerance promise.

Rubber Vulcanization Analysis

Our quality control regimen begins with a rigorous inspection of the materials used, to ensure that the raw rubber compounds meet the specified durometer and tensile strength standards. During production, vulcanisation analysis uses oscillating disc rheometry to monitor crosslink density, optimising cure time and temperature to prevent under- or over-curing defects. Vulcanisation analysis is pivotal as it dictates the durability, dimensional stability and resistance to thermal degradation of the material, which directly correlates to the operational lifespan and performance consistency of our rollers.

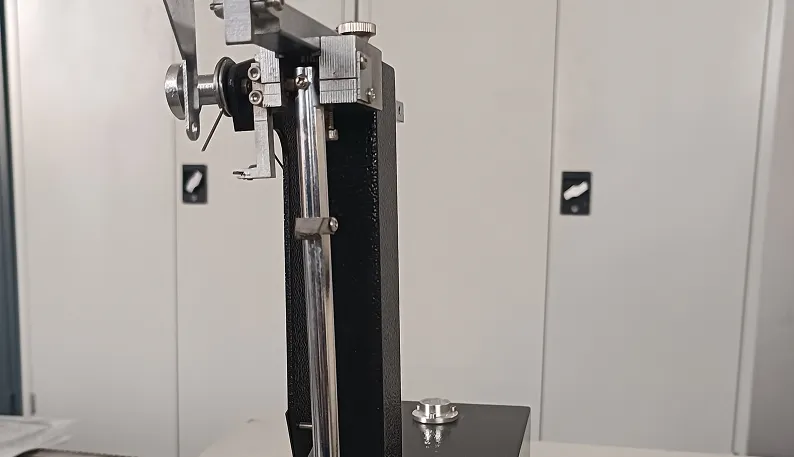

Rubber Impact Tester

Our quality assurance protocol uses a multi-stage inspection framework that integrates advanced material science analytics. Finished rollers undergo simulated service-condition impact trials using our rubber impact tester. This tester acts as a safeguard against premature fatigue failure, ensuring compliance with standards. By quantifying resilience to sudden loads, the tester directly informs adjustments to material formulations, mitigates catastrophic failures in the field and upholds our reputation for delivering rollers that can withstand operational shocks without compromising on quality.

Compression Testing

Our quality framework incorporates both destructive and non-destructive evaluations to ensure structural integrity. Finished products undergo cyclic compression fatigue testing to simulate decades of operational stress. Compression analysis is crucial as it validates load-bearing capacity, prevents dimensional collapse under stress and correlates directly with service life expectancy. By quantifying material resilience thresholds, we can prevent premature failure and ensure that every roller delivers consistent performance in high-torque industrial applications without deformation or compromise.

Laser Dimensional Inspection

Our ISO 9001-certified quality protocol focuses on laser metrology for precise, non-contact verification. Each roller is scanned to validate concentricity, straightness and critical dimensions using optics with a resolution of 0.001 mm, which exceeds industry norms. This technology is indispensable as it eliminates tactile measurement errors and enforces tolerance discipline. By achieving concentricity thresholds of ±0.01 mm, we guarantee rotational stability, minimise vibration-induced wear and deliver rollers that perform flawlessly in high-speed, high-load industrial environments.