Custom & Design Service

Our Design Service

Industrial excellence is never generic, uniqueness defines success. Every production line has different demands, such as extreme temperatures, aggressive chemicals or ultra-delicate materials. Off-the-shelf rollers often fail: they experience premature wear in corrosive environments, produce inconsistent finishes on speciality films and compromise performance in non-standard geometries. Without optimised design, efficiency gains remain unrealised.

Yulong transforms these challenges into engineered solutions. As application specialists, we combine material science with meticulous design. We customise production according to our customers’ specific requirements, from R&D and design to raw material selection, rubber roller moulding, vulcanisation, processing and testing. This enables us to provide you with the most suitable rubber roller products.

Precision Begins with Partnership

Our seasoned application engineers conduct a forensic analysis of your process, mapping exact equipment contexts, decoding operational parameters such as line speeds, thermal cycles, and chemical exposures. We isolate pain points of operation through deep conversation. Rollers engineered not just to fit, but to elevate—provide advice on improving the roller coating process and reducing paint usage. Trust us to reimagine your roller performance, from concept to measurable outcomes.

- Optimize transfer efficiency

- Reduce paint usage

- Maintain consistent film thickness

Originates in Various Material Selection

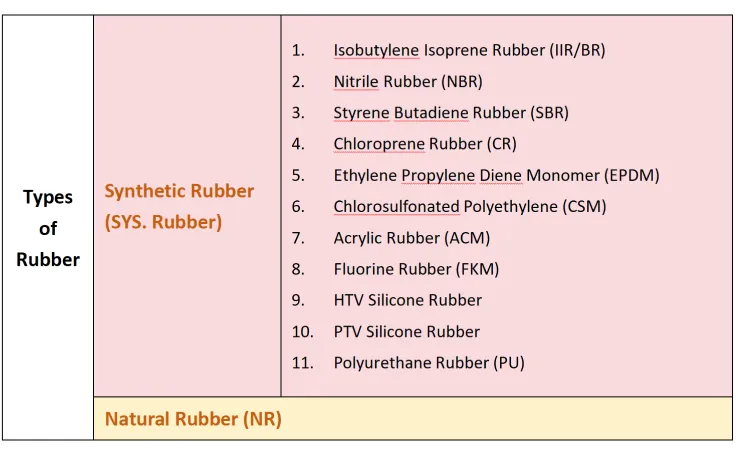

We engineer custom solutions using an extensive elastomer library that is optimised for industrial demands. In addition to standard materials, we formulate compounds containing fillers such as carbon black and aramid to enhance thermal conductivity, chemical resistance and durability. Whether you are looking to optimise paint reduction, extend the lifespan of your products, or achieve flawless finishes, our material science can transform constraints into competitive advantages.

Precision Tailored Roller Solutions: Built Beyond Standard Limits

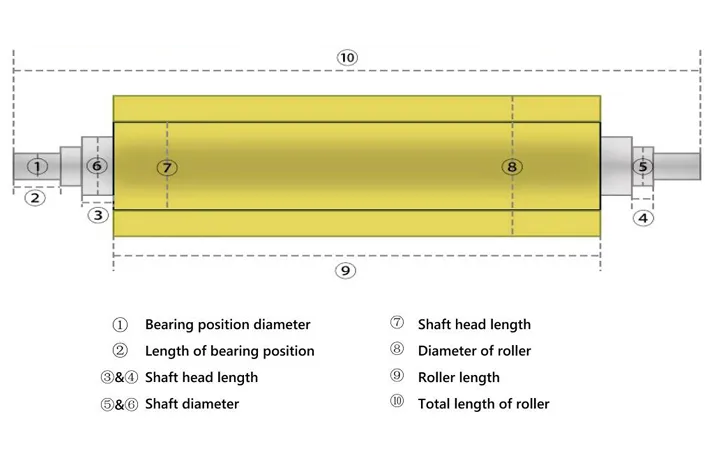

We fabricate rollers tailored to client-specified dimensions, including bearing journal and shaft configurations, roller body diameters, and total assembly lengths. Our expertise extends to complex geometries: hollow rollers with spiral/axial cooling channels, tapered profiles for tension control, and lightweight carbon-fiber cores for weight-critical applications. This commitment to dimensional integrity ensures seamless integration into your machinery, balancing structural rigidity, operational efficiency, and longevity.

Precise Production Process

Our manufacturing process is characterised by meticulous coordination, combining advanced 3D engineering with traditional craftsmanship. Each roller evolves through a series of calculated stages, from digital prototyping and precision tooling to controlled fabrication and multi-tiered validation. This process culminates in flawless assembly and logistics. This structured yet adaptive workflow ensures that every component meets your operational requirements and integrates seamlessly into your processes.

1

3D Drawing Out

2

Mould Making

3

Production

4

Quality Inspection

5

Assembly Line

6